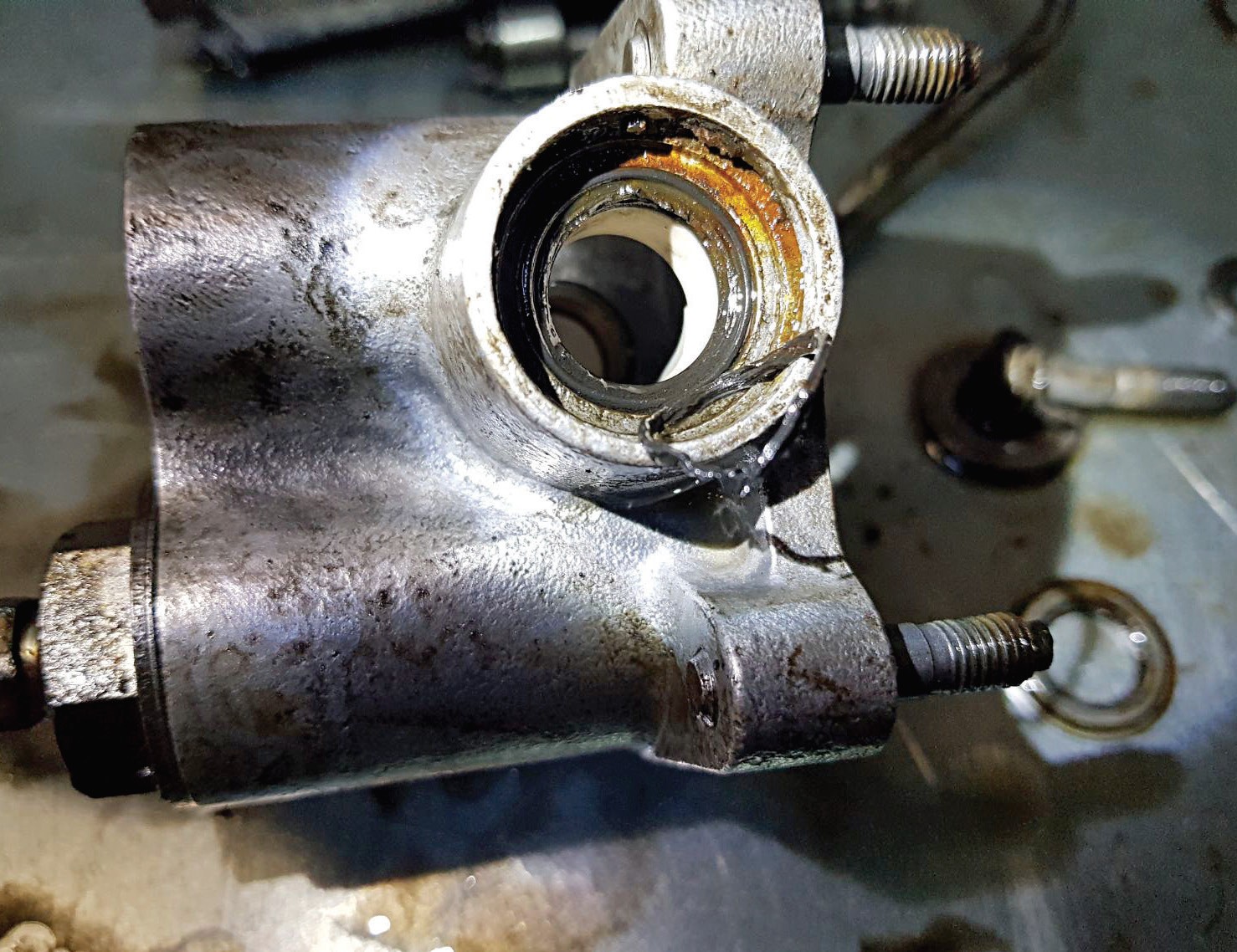

We are frequently finding that the height control casings are scrap on old units (approx. 30%), mainly due to old age and corrosion where the seal sits beneath the circlip, see image below.

Signs of old age and corrosion of the Height Control Valve casing

As a result we have manufactured a new height control valve casing. CNC machined from from solid aluminium and then lightly shot blasted on the non working surfaces to mimic the original casting look, it is finished with a laser etched logo.

Our brand new height control valve casing manufactured by PH Components

Following a number of issues with the quality of rubber O rings, we can confirm that our O rings are now manufactured to a known consistent compound formula with full traceability, independently tested to ensure volume increase (swell) and that no negative swell (shrinkage) occurs.

An example of an O-ring failing in the Height Control Valve caused by the rubber compound reacting with RR363 Brake Fluid

The height control valves themselves are a unit that we fully rebuild and test inhouse. Each valve is fully stripped, aqua-blasted and inspected for damage (in particular the housing, piston and valve). All ports are measured and internal components cleaned. A new main control shaft and bushes are fitted along with new O rings and outer nuts and washers. We believe other units on the market do not replace the shaft.

The rebuilt unit is fitted to our hydraulic test rig in order to carry out a full function and pressure test. Extreme care must be taken when replacing these valves to ensure that the pipes are refitted into the correct ports. The valve is supplied fitted with the ram feed hose and the low pressure return hose (CD6244) is also supplied - please ensure that this is replaced. It is also imperative that the two restrictor valves are cleaned out and checked and a new O ring fitted.

An example of a height control valve prior to reconditioning

One of our fully rebuilt height control valves after being reconditioned in-house